In the world of chocolate production, tempering chocolate is a critical step that ensures a smooth texture, glossy finish, and extended shelf life. Therefore, for various chocolate manufacturers, choosing the right chocolate production machines for tempering chocolate is essential, which is not only to optimize production efficiency but also to guarantee product quality. However, the tempering machine price can vary significantly based on a range of factors. At Gondor Machinery, we specialize in designing and manufacturing high-performance chocolate processing machinery. Moreover, with years of experience serving global clients, we’ve identified six key factors that directly influence the pricing of chocolate tempering machines. What’s more, understanding these will help you make smarter purchasing decisions tailored to your production needs.

Machine Capacity and Throughput

One of the primary factors affecting the tempering machine price is its processing capacity, which is typically measured in kilograms per hour (kg/h). Because of this, A machine designed for high-volume industrial chocolate production will naturally cost more due to its robust structure, larger motor systems, and enhanced efficiency. Whether you’re running a small artisanal chocolate studio or a full-scale factory, selecting the chocolate tempering machine with appropriate capacity is crucial to balancing cost and performance.

Heating and Cooling System Design

Effective tempering chocolate requires precise temperature control through a combination of heating and cooling cycles. In genetal, advanced chocolate making machines offer dual or independent temperature zones, high-precision sensors, and programmable logic control (PLC) systems. These upgrades ensure consistency but also increase the overall tempering machine price. In contrast, basic machines for tempering chocolates may be more affordable but lack the accuracy required for high-end chocolate products.

Level of Automation and Smart Control

In addition, as automation becomes the norm in modern chocolate production lines, fully automatic machines for tempering chocolate are in high demand. What’s more, our tempering machines have features, such as touchscreen interfaces, automated temperature adjustments, and integration with other processing lines, which not only simplify operations but also improve consistency and safety. However, these intelligent features contribute to a higher machine price. At Gondor Machinery, we offer scalable automation options to match your budget and factory setup.

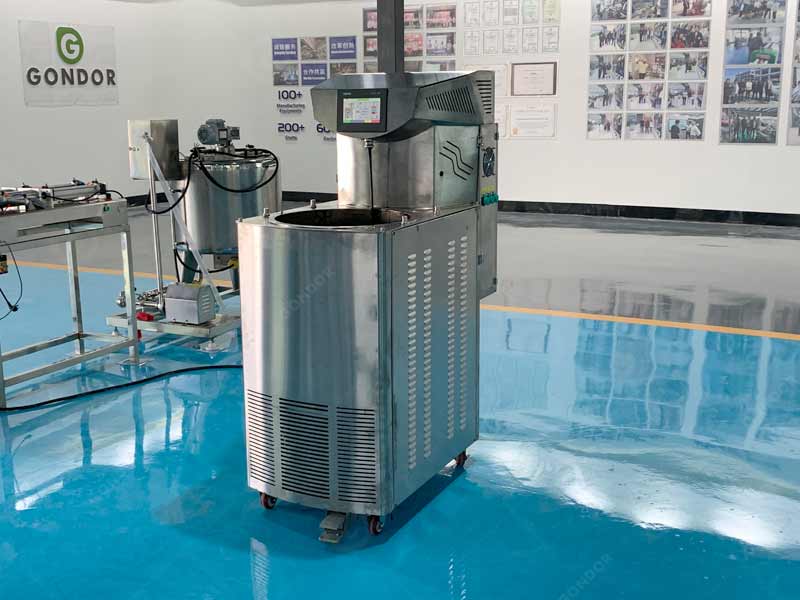

Material Quality and Build Standards

As we all know, all food processing equipment must meet strict hygiene and safety requirements. Our machines for tempering chocolates are built using food-grade 304 or 316 stainless steel, with superior welding, polishing, and surface treatment. Therefore, while high-quality materials and craftsmanship increase durability and safety, they also influence the tempering machine price. On the contrary, tempering machines made with thinner steel or substandard components may seem cost-effective initially but often result in higher maintenance and replacement costs over time.

Brand Value and After-Sales Service

When investing in a machine for tempering chocolate, you’re not just buying hardware, but you’re choosing a long-term partner. As an established chocolate making machine manufacturers, Gondor Machinery offer comprehensive after-sales support, including installation assistance, remote troubleshooting, and fast parts supply. Moreover, our global client base trusts us for reliability, technical expertise, and responsive service. These added values are often reflected in the pricing structure and can make a significant difference in long-term operational success.

Customization Requirements

Finally, yet importantly, every chocolate production facility is unique. Some clients may require custom features such as multi-channel output, integrated conveyor connections, or modular control panels. Therefore, the more tailored your equipment, the higher the design and production costs. That said, a well-customized machine for tempering chocolate can drastically enhance efficiency and reduce downtime, which makes it a smart investment despite a higher initial tempering machine price. At Gondor Machinery, we offer flexible customization to ensure your machine aligns perfectly with your product specifications and workflow.

Making the Right Investment in a Chocolate Tempering Machine

Therefore, choosing the right chocolate tempering solution requires more than just comparing tempering machine price tags. It’s about understanding your production goals, quality expectations, and operational constraints. At Gondor Machinery, we combine engineering precision with industry insight to deliver equipment that adds real value to your production line. If you’re looking for a durable, high-performance machine for tempering chocolate, or want expert advice on tempering chocolate processes and machine selection, get in touch with Gondor Machinery today. Our team is here to guide you every step of the way.