With the rapid development of the global food industry, chocolate production is transforming traditional technology into intelligence, scale, and high efficiency. Increasingly, chocolate manufacturers are investing in upgrading their core equipment, including chocolate production machines, commercial chocolate melting equipment, and chocolate bar wrapping machines, to meet the growing demand for high-quality and diversified products.

Chocolate Production Machine: Realizing Intelligent Manufacturing

Modern chocolate production machines combine the functions of automatic feeding, precise mixing, continuous grinding, and mold forming, which is the core power of chocolate processing. Whether it is milk chocolate, dark chocolate, or sandwich chocolate, these machines can achieve integrated treatment from raw materials to finished products, significantly improving production capacity and quality control levels. According to Statista, a market research organization, the global demand for industrial chocolate is growing at an annual rate of over 4%, which promotes the manufacturers’ high dependence on automatic production lines.

Commercial Chocolate Melting Equipment: Stable Temperature Control

In chocolate processing, the melting process is the key link to determine the fluidity and crystal structure of products. Our new generation of commercial chocolate melting equipment is specially designed for medium and large factories and high-end application scenarios, and has the following core advantages:

Chocolate Bar Wrapping Machine: Automatic Packaging

Product packaging is the “last mile” for chocolate to enter the market. An efficient chocolate bar wrapping machine not only improves production efficiency, but also directly affects the brand image. Traditional manual packaging has long been unable to meet the demand of thousands of products per hour.

Global Services Help Localized Operations

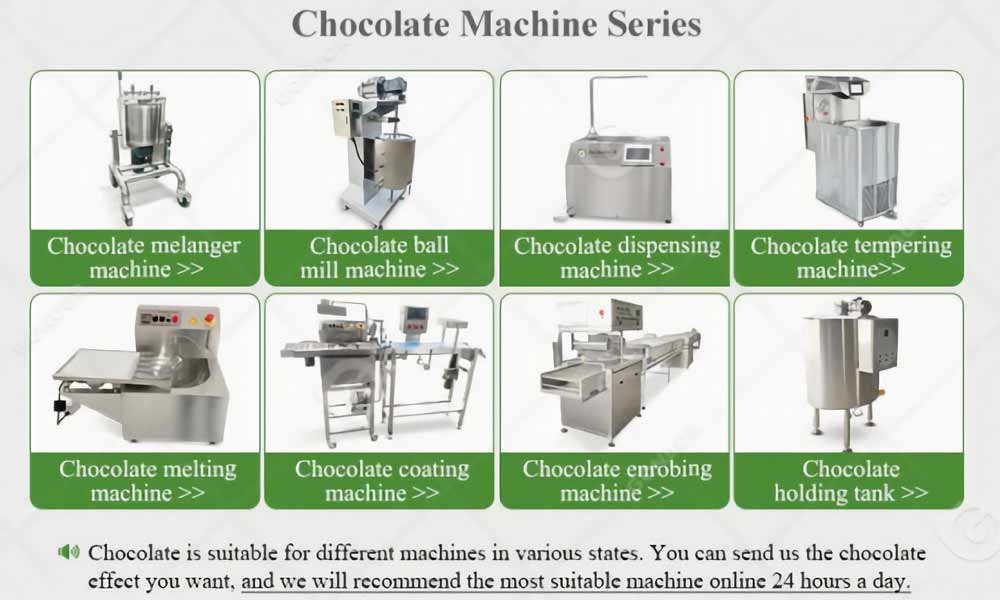

In addition to the above equipment, we also provide the following related products to help customers build a complete production line:

- Chocolate Enrobing Line: It is widely used for coating biscuits and nuts.

- Chocolate Cooling Tunnel: To ensure the quick setting of finished products.