With the increasing global demand for high-quality chocolate, the chocolate manufacturing industry is accelerating the transformation of intelligence and automation. Chocolate machinery is developing in the direction of specialization, especially small and medium-sized enterprises have a strong demand for efficient and flexible chocolate-making machines for small businesses, while high-end factories are increasingly relying on professional chocolate tempering machines to upgrade their production lines.

Global Market Demand for Chocolate Machinery Has Surged

In the past few years, global chocolate consumption has increased by more than 3% per year. In order to meet the increasingly diversified market tastes, from handmade chocolate workshops to large chocolate manufacturers, they are seeking to upgrade their equipment. The innovation of chocolate machinery not only improves the production efficiency but also makes a breakthrough in hygiene standards, energy conservation, and environmental protection, making the production process more intelligent and controllable.

New Opportunities for Small Businesses

With the rise of the personalized consumption trend, more and more entrepreneurs are devoting themselves to the field of fine chocolate production. This has also led to the expanding demand for chocolate-making machines for small businesses. For small-scale production needs, such equipment usually has the following characteristics:

- Compact size, suitable for limited space.

- The operation is simple, and the training cost is reduced.

- Multi-functional integration, to meet a variety of tastes, innovations.

- Fast return on investment, helping to make quick profits.

Professional Chocolate Tempering Machine in Focus

For professional chocolate manufacturers, temperature control technology is the key link to determine the luster, texture, and taste of products. An efficient and accurate Chocolate Tempering Machine Professional is very important. The imported chocolate tempering machine professional equipment, adopts an advanced microcomputer control system, which can realize:

Future Trend: Parallel Intelligence and Diversification

Future chocolate manufacturing equipment will pay more attention to intelligent interconnection and flexible configuration. For example, through the Internet of Things (IoT) technology, remote monitoring of equipment, data analysis, and optimization of production processes can be realized, or through modular combination, the customized needs of customers of different scales can be met.

Gondor’s Promise

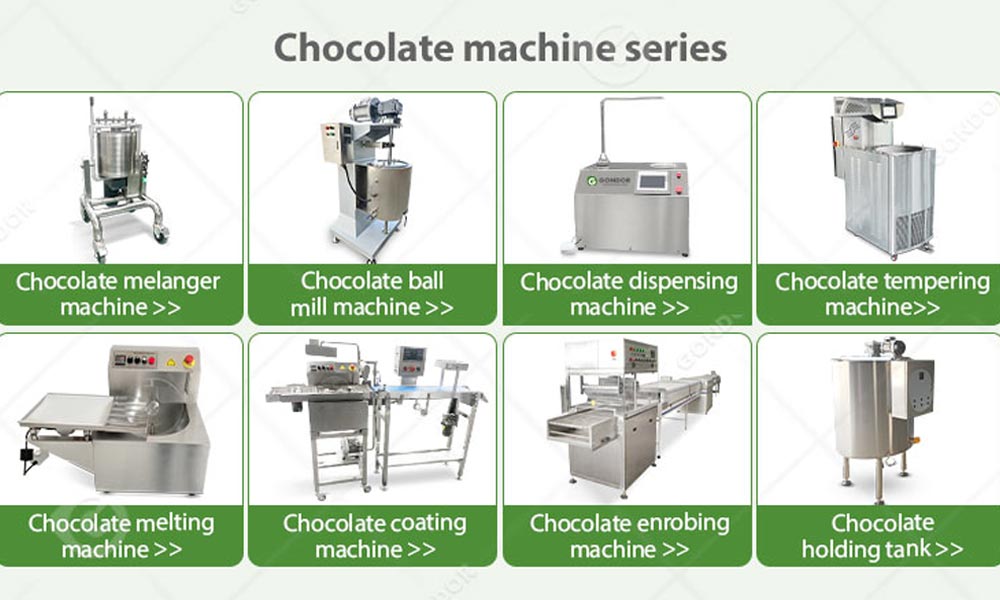

As a leading supplier of chocolate machinery, we also provide a variety of related equipment synchronously, including: