Today, with the rapid development of the food processing industry, an efficient, intelligent, and easy-to-operate baking equipment is becoming the first choice for customers all over the world is Gondor’s multifunctional cocoa bean roaster. This machine is not only suitable for peanuts, but also widely used for drying and baking many kinds of granular materials, such as chestnuts, almonds, broad beans, coffee beans, melon seeds, walnuts, etc. It is industrial equipment that truly realizes multiple functions.

| Electric heating |

| Model |

Voltage |

Power |

Motor Power |

Machine Size (mm) |

Capacity |

Weight |

| EGD-1 |

380v |

22.5kw |

1.1kw |

2900x1450x1650 |

100kg/h |

700kg |

| EGD-2 |

380v |

36-44kw |

2.2kw |

2900x2100x1650 |

200kg/h |

1300kg |

| Gas heating |

| Model |

Gas Consumption |

Motor Power |

Machine Size (mm) |

Capacity |

Weight |

| GGD-1 |

2-3kg/h |

1.1kw |

2900x1250x1750 |

100kg/h |

700kg |

| GGD-2 |

4-5kg/h |

2.2kw |

2900x2100x1700 |

200kg/h |

1300kg |

Application Scenarios of Cocoa Roasting Machine

Food Processing IndustryNut Processing PlantsSnack Food Factories

Peanut roaster is widely used in the food industry, which is used to dry and ripen all kinds of nuts and beans, and improve the taste and shelf life of products.

In the nut processing plant, the equipment can be used for baking raw materials such as peanuts, almonds, and chestnuts, to realize batch and automatic production.

It is suitable for baking pretreatment of spiced peanuts, fried melon seeds, and other flavored snack foods, and provides a stable thermal processing basis for subsequent seasoning and packaging.

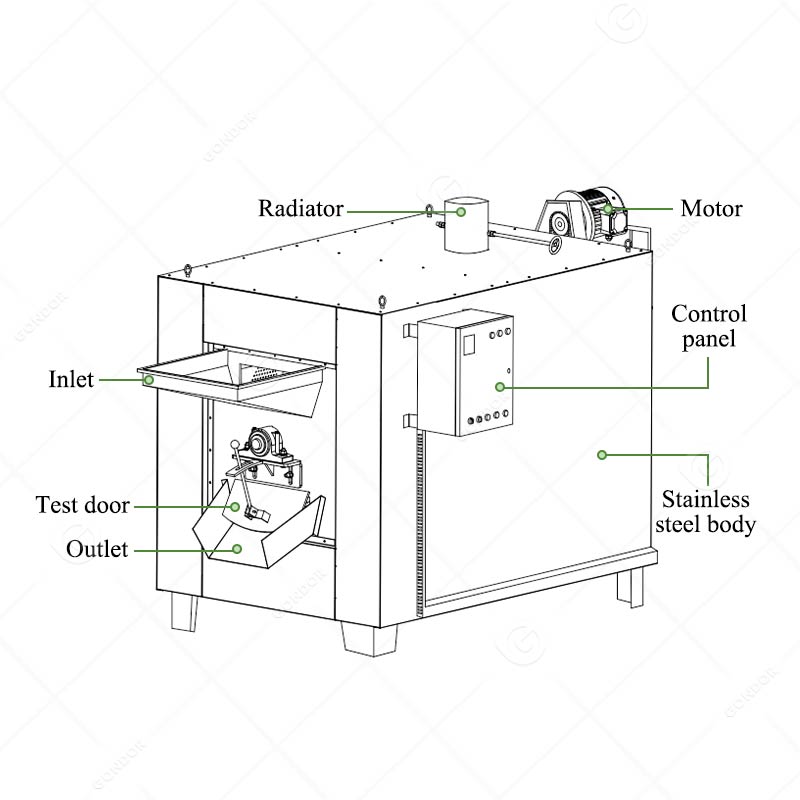

Cocoa Bean Roaster Features and Highlights

Double Heating Options

- Support electric heating and gas heating to meet the energy structure needs of different customers.

- Heat is conducted by infrared radiation and hot air convection, and the baking process is completed quickly and evenly.

Intelligent Temperature Control

- The temperature adjustment range is Room Temp-300°C, which can meet the baking process requirements of different materials.

- Equipped with a timing automatic control system to improve operation accuracy and reduce manual dependence.

Rotating Drum Design

- Adopt a clockwise automatic stir-frying and counterclockwise automatic discharging system to ensure uniform heating of materials and prevent local over-baking or raw materials.

Large Capacity Baking

- For commercial mass processing design, each batch can handle a large number of materials, greatly improving production efficiency and reducing unit cost.

Why Choose Our Cocoa Bean Roaster Machine?

Easy OperationFood-Grade Stainless SteelWide ApplicationEnergy Saving & Eco-Friendly

Even a novice can get started quickly. The design of the intelligent control panel is simple and clear./su_tab]

The whole baking process is continuous and stable, almost without interruption, suitable for long-term operation.

It is made of 304 stainless steel, which is corrosion-resistant and easy to clean, and meets international food safety standards.

Not only suitable for traditional nuts, but also for the secondary processing of spiced peanuts, glutinous rice, and other special flavor foods.

The heat energy utilization rate is high, especially the electric heating model, which is more environmentally friendly and convenient for urban factories to use

Open a New Era of Nut Baking

To help you achieve a more efficient nut processing process, we also provide a series of supporting equipment, such as:

Choosing our cocoa roasting machine is not only a choice of equipment, but also a more intelligent, efficient and hygienic future. Consult immediately and start the efficient way of nut processing!