With the continuous growth of global demand for high-quality chocolate, the upgrading of chocolate production equipment has become the focus of attention in the industry. This paper will focus on the chocolate ball mill machine price, the production process of chocolate and cacao roaster, deeply analyze the industry trends and equipment applications, and help global customers grasp the market pulse.

The Charm of Chocolate Begins with Cacao Roaster

The manufacture of high-quality chocolate begins with the roasting of cocoa beans. The cacao roaster is an indispensable part of the whole chocolate production line. Through precise temperature control and time management, the modern cocoa roaster can retain the aroma components of cocoa beans and remove bitter substances, laying the foundation for subsequent grinding and refining.

Technical Highlights

- A hot air circulation system to improve thermal efficiency.

- Multi-stage temperature control program, suitable for different types of raw beans.

- Automatic tumbling structure ensures uniform baking.

Production Process of Chocolate

Understanding the production process of chocolate will help enterprises to better choose the matching equipment chain. A typical chocolate production process includes:

Extracting pure cocoa kernels.

To finely grind cocoa nibs to form a smooth cocoa liquor.

Mixing with sugar, milk powder, and other ingredients.

Refine the particles and improve the taste.

The final refinement is completed by a chocolate ball mill.

To ensure the stability of the crystal structure of chocolate.

The chocolate is shaped, cooled, and packaged for sale.

Chocolate Ball Mill Machine Price Has Become a Hot Spot

In recent years, with the fluctuation of global equipment manufacturing costs, the chocolate ball mill machine has become an important decision-making factor in the procurement process.

Key Influencing Factors

- Motor power and energy efficiency.

- Grinding medium.

- Control system (PLC automation vs manual control).

- Whether to integrate the temperature control and circulation system.

Industrial Chain Linkage

Modern chocolate manufacturing is no longer a stand-alone operation, and the whole line integration and intelligent control are gradually becoming the mainstream. In addition to the cacao roaster and ball mill machine, the following equipment has also attracted the attention of global buyers:

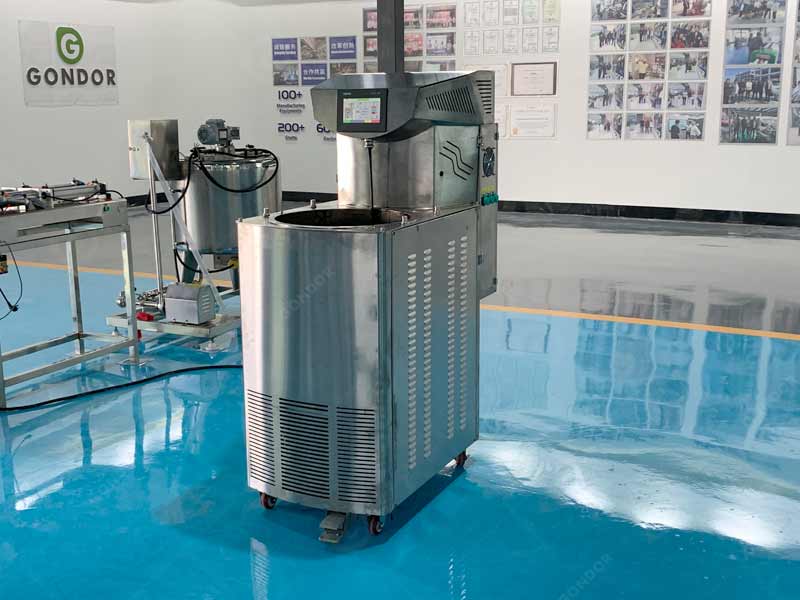

- Chocolate Tempering Machine: Enhance the luster and shelf life of products.

- Tabletop Chocolate Enrober: Suitable for products such as sandwiches and nuts.

Whether you are a newly-started enterprise in the chocolate industry or a mature factory seeking to upgrade equipment, we can provide you with a full set of chocolate equipment suggestions and after-sales service.