In the chocolate production industry, the chocolate tempering wheel is the key equipment to improve production efficiency and product quality. Whether making chocolate candy, chocolate shells, or adding perfect chocolate liquid to food surface coating, the chocolate pouring machine can greatly simplify the process and improve the production effect. This chocolate pouring machine has an advanced design and simple operation, which can meet the needs of efficient and accurate chocolate production and is an ideal choice for bakeries, food processing factories, and the candy industry.

| Model | Capacity | Power | Voltage | Size |

| GD-CMPM-08/15 | 5 kg-60 kg/h | 0.6-2kw | 220v |

450*550*550mm-1220*780*1290mm |

|

GD-CMPM-30/60 |

10 kg-40 kg/h | 1.8-2kw | 220v |

900 * 670 *1230mm-1130 * 750*1300mm |

| GD-CMPM-15*2 | 10-30kg/h | 2kw | 220v |

1070*600*640mm |

|

GD-CMPM-24 |

15-45kg/h | 2.2kw | 220v |

1275* 660 *570mm |

Chocolate Tempering Wheel Application Field

This chocolate wheel tempering equipment is widely used in food processing fields such as chocolate factories, the candy industry, and bakeries, especially for mass production of chocolate candy, shell coating, and other chocolate products. Whether it is mass production or customized products, it can provide a stable and reliable solution, which is suitable for chocolate-coated foods such as chocolate candy, biscuits, candies, and dried fruits.

Functional Characteristics of Wheel Tempering Machine

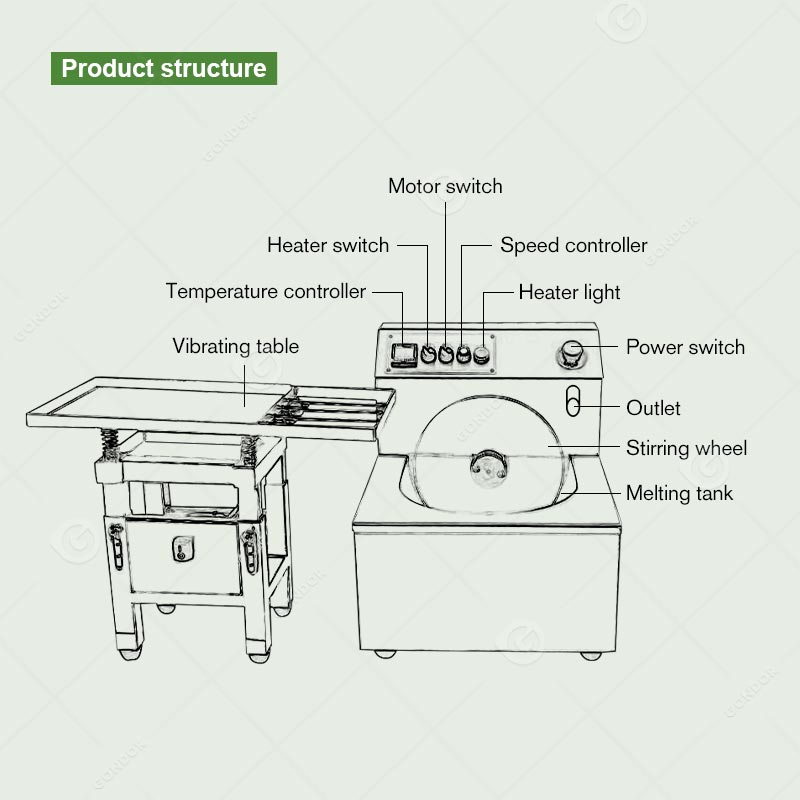

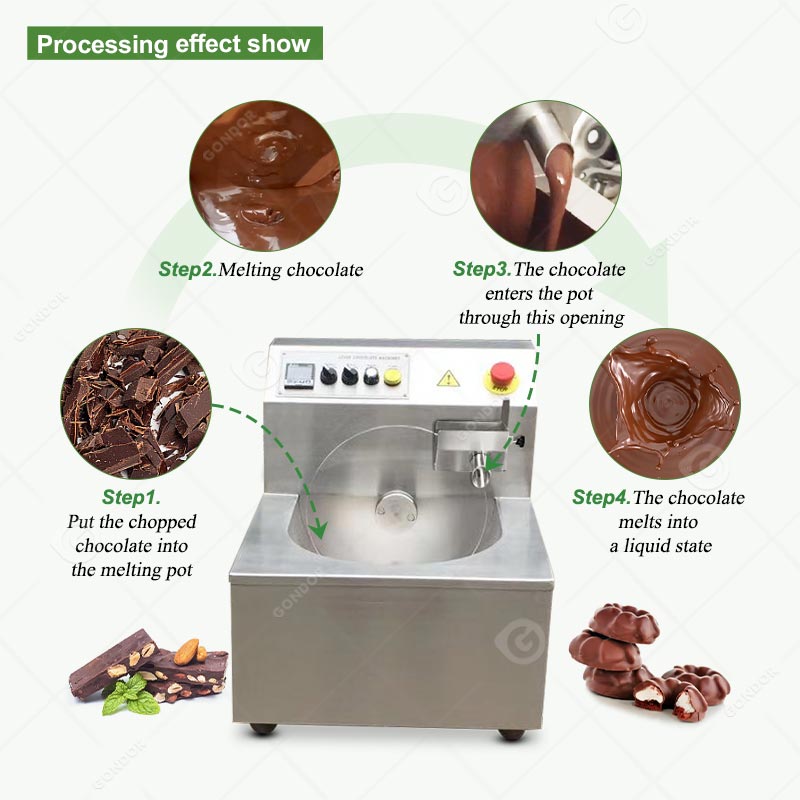

Chocolate Wheel Tempering Equipment Operation Process

First, put the chocolate raw material into a heating device, and use an efficient heating system to heat and melt the chocolate into a liquid state. Temperature control in this process is very important to ensure that the chocolate reaches the best melting state.

The melted chocolate liquid will be transferred to the temperature control system to keep a constant temperature. This will ensure that the chocolate does not fluctuate in the subsequent production process and maintain its texture and taste.

The liquid chocolate is accurately poured through the stainless steel outlet, and the bubbles in the chocolate are eliminated by the vibration function. Thus, the chocolate surface is smooth, the finished product is shinier, and it is easy to demold.

Easily Improve the Efficiency of Chocolate Production

With the continuous pursuit of production efficiency and quality in the chocolate industry, the chocolate tempering wheel has become an essential equipment for modern production with its excellent functions of temperature control, pouring, and vibration. It not only improves production efficiency, but also ensures that every chocolate product is perfect. If the processing process needs to be further optimized, it can be used together with our chocolate tempering machine or chocolate depositor machine to improve the efficiency of the overall production line. Choose our chocolate pouring machine to make your chocolate more efficient and meet the demand for high-quality chocolate in the global market.