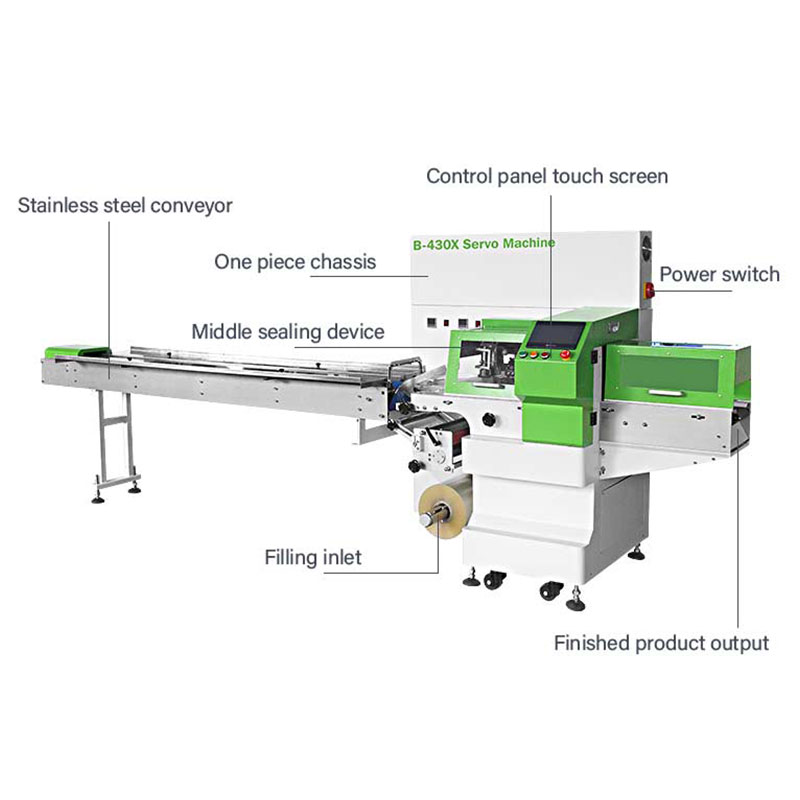

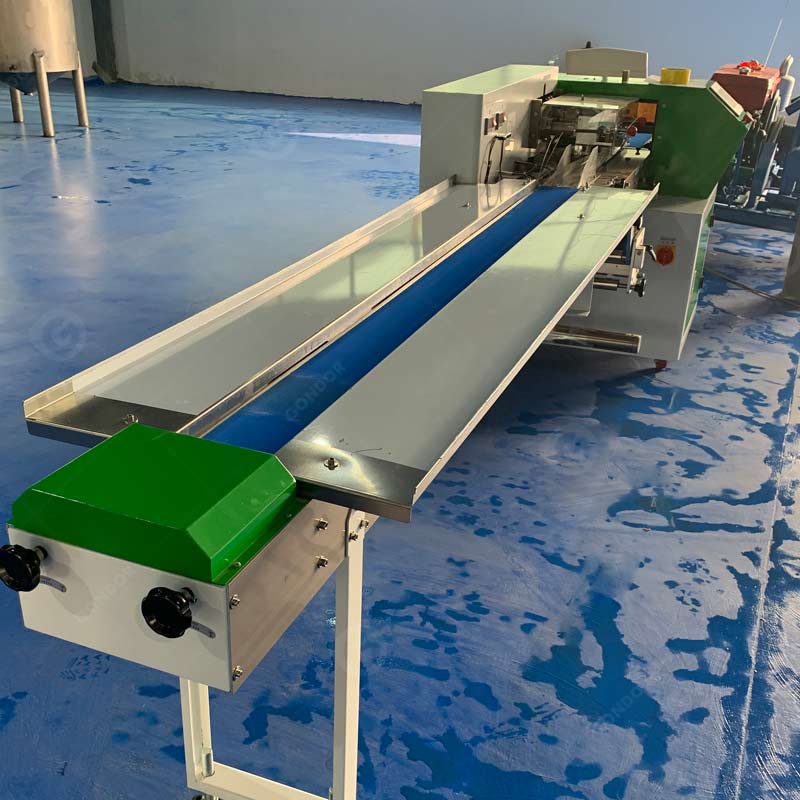

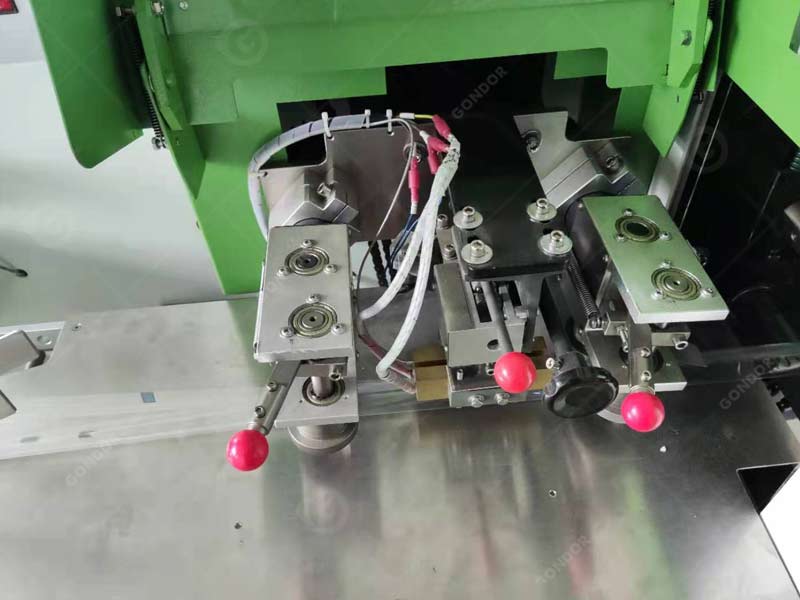

The chocolate wrapping machine is a highly automated packaging equipment, which is widely used in food, daily chemical, medicine, hardware, and other industries. It adopts an advanced servo control system and continuous film wrapping technology to efficiently and accurately package products into pillow bags with a beautiful appearance and strong sealing. The device is equipped with a touch screen interface, which supports multiple languages and is easy to learn. The whole structure includes feeding, molding, sealing, and cutting modules, which work together to ensure the efficient and stable packaging process.

|

Model

|

XZL-250

|

XZL-320

|

XZL-350

|

XZL-450

|

XZL-600

|

|

Width of the film

|

Max250mm

|

Max320mm

|

Max350mm

|

Max450mm

|

Max600mm

|

|

Length of the bag

|

65-190/120-280 90-220mm

|

5-190/120-280 90-220/150-330mm

|

65-190/120-280 90-220/150-330mm

|

130-450mm

|

120-500mm

|

|

Width of the bag

|

30-110mm

|

50-160mm

|

50-160mm

|

50-180mm

|

100-280mm

|

|

Products are highly

|

Max.40-55mm

|

Max.40-60mm

|

Max.40-60mm

|

Max.75mm

|

Max.110mm

|

|

Roller diameter

|

Max.320mm

|

||||

|

Packing speed

|

40-230bag/min

|

40-230bag/min

|

40-230bag/min

|

30-150bag/min

|

20-230bag/min

|

|

Power

|

2.4kw

|

2.6kw

|

2.6kw

|

3.2kw

|

3.6kw

|

|

Size

|

3770*670*1450

|

3770*720*1450

|

4020*770*1450

|

4020*820*1450

|

4020*920*1460

|

|

Weight

|

450kg

|

500kg

|

580kg

|

650kg

|

680kg

|

|

Optional configuration

|

Code punching machine, inflatable device, cake falling machine, material handling machine

|

||||

|

Packaging materials

|

Such as single heat seal BOPP/ composite film, such as OPP composite, PE, PET composite, PEE

|

||||

|

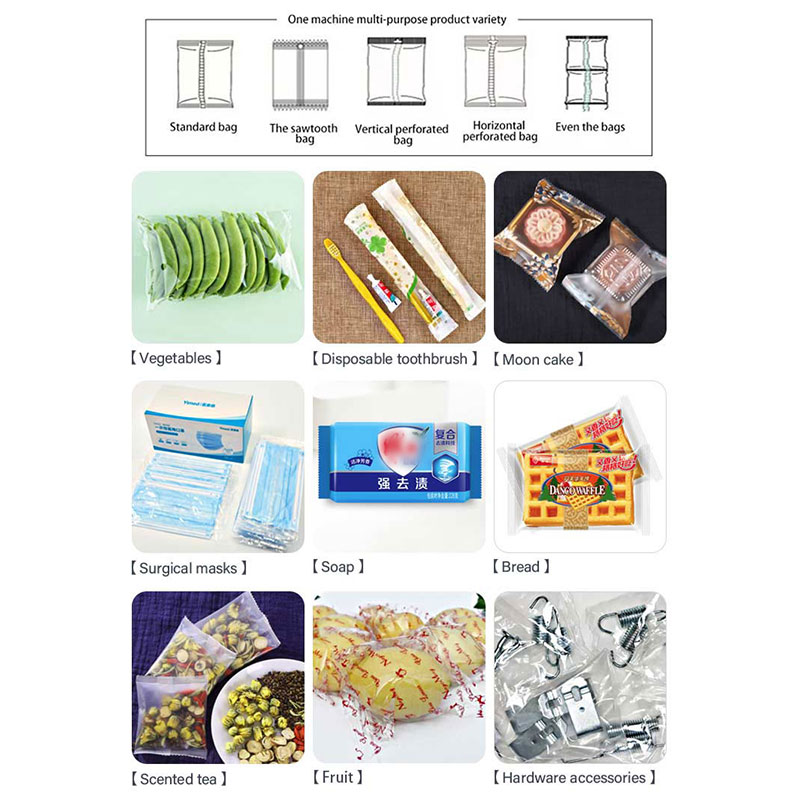

Bag shape

|

Back seal packaging (round hole and butterfly hole can be customized)

|

||||

|

Transverse seal edge grain

|

Mesh type sealing, stripe type sealing, knife edge serrated mouth, flat mouth, plus very easy to tear

|

||||

Demand Industries of Chocolate Packaging Machine

Thanks to its excellent versatility and flexibility, the pillow packaging machine can be applied to product packaging of various shapes and specifications:

Efficiency Advantage of Chocolate Packing Machine

Intelligent and Efficient Packaging Solution

Our chocolate wrapping machine is not only suitable for standard product packaging, but also can customize modules and functions according to customer products. Welcome to learn about our other intelligent equipment, including the vertical packaging machine, ten-head scale, etc., to help you build a complete and efficient packaging production line. Want more product information and a price plan? Please contact our international sales consultant immediately!