As the global dessert market continues to evolve, ice cream products are becoming more refined, creative, and visually appealing. Therefore, to meet growing demand for high-end frozen treats, a Bolivian customer has successfully partnered with Gondor Machinery to establish a fully automatic chocolate-covered ice cream production line. And this line integrates machines from chocolate tempering to final product display, which delivers consistent quality and efficiency throughout the process. Check below to get the project details and obtain a tailored solution for your own project!

Project Background: Elevating Market Value with Premium Ice Cream Creations

The customer, a well-known ice cream and frozen dessert manufacturer in Bolivia. And he sought to upgrade their product offering by introducing a unique chocolate-coated ice cream line. With the increasing local demand for premium sweets, the goal was to launch a product that stands out in both appearance and taste, which can enhance brand competitiveness and market share.

After evaluating multiple equipment suppliers, the customer chose Gondor Machinery for our rich experience in food processing equipment and its ability to deliver customized, high-performance solutions tailored to specific production needs.

Equipment Purchased: Specialized Chocolate Machinery for Quality Results

At Gondor Machinery, we place great importance on understanding and meeting customer needs. Therefore, we are committed to delivering tailor-made food processing solutions based on each client’s specific production process and market positioning, which ensures optimal efficiency, product quality, and ease of operation.

As for this customer in Bolivia, to support the customer’s production goals, Gondor Machinery provided a set of core machines that play a critical role in the ice cream coating process:

Chocolate Tempering Machine

This chocolate tempering machine heats chocolate to the optimal coating temperature, and it ensures smooth texture and glossy finish. At the same time, it prevents issues like blooming or grainy texture, which can negatively impact product appearance and taste.

Chocolate Enrobing Machine

It is designed to evenly coat ice cream bars or cones with a layer of tempered chocolate. The automated process of chocolate enrobing machines guarantees consistent coating thickness and appearance while increasing overall production speed.

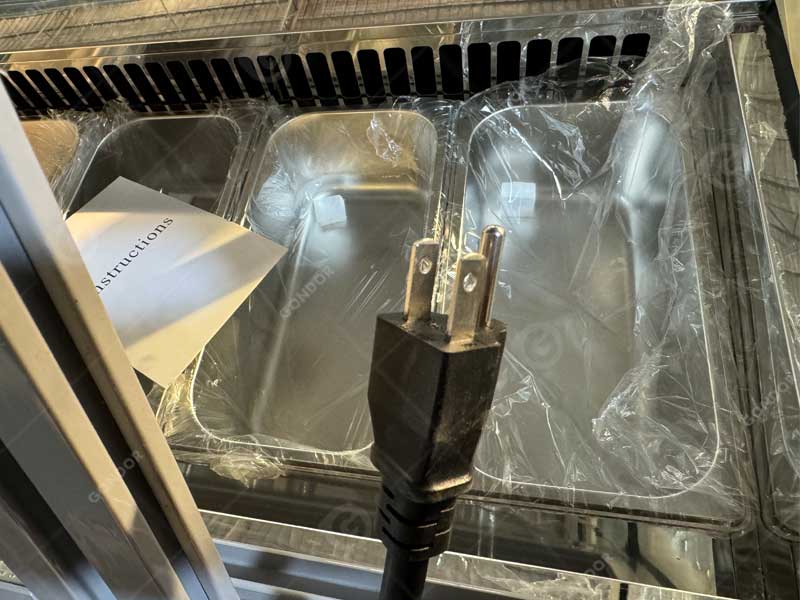

Ice Cream Display Freezer

Combining storage and presentation, this ice cream display freezer uses precise temperature control to preserve the integrity of the chocolate coating while showcasing the finished products attractively. It enhances point-of-sale appeal and extends product shelf life.

Production Process Overview: Streamlined, Automated, and Efficient

The production line was carefully designed to optimize flow and minimize manual handling, which achieve greater output with less labor. The workflow is as follows:

Customer Feedback: Satisfied with Quality, Efficiency, and Market Results

Following the successful installation and operation of the production line, the customer shared very positive feedback:

Visually Appealing Products

The chocolate coating is smooth and uniform, which significantly enhances product presentation.

30% Increase in Efficiency

Automated processes reduced labor requirements and boosted production output.

Strong Market Response

The new chocolate-covered ice cream has received excellent reviews from local consumers.

Professional Display Cabinet

Modern design and reliable cooling improved brand image and in-store product visibility.

Why Choose Gondor Machinery: One Partner, Full Solution

Gondor Machinery offers more than just equipment, we provide complete, practical solutions for ice cream and chocolate processing:

Integrated Process Support

From chocolate tempering to retail display, we deliver full production line solutions.

User-Friendly Design

Chocolate making machines are easy to operate, clean, and maintain.

Global Service

Remote technical support and fast international delivery ensure peace of mind for overseas clients.

Proven Track Record

Years of experience and successful global installations reinforce our reputation.

Win-Win Collaboration with Gondor Machinery – Your Ideal Partner

This collaboration between Gondor Machinery and our Bolivian customer marks another milestone in delivering high-quality, customized solutions for the global dessert industry. Our advanced chocolate and ice cream machinery helps clients create premium products that delight customers and stand out in competitive markets. As a global expert in food processing machinery, Gondor machinery will provide chocolate making machinery to help our clients boost product value and market competitiveness.

If you’re planning to build an ice cream, chocolate, or other dessert production line, we invite you to contact us. Gondor Machinery — your trusted partner for innovative food processing solutions. Contact us today for your personalized production line plan.