In recent years, with the rapid rise of global consumers’ demand for high-quality chocolate, chocolate making machine manufacturers are welcoming unprecedented development opportunities. From small handmade chocolate workshops to large industrial production lines, more and more manufacturers tend to be more intelligent, efficient, and stable in equipment selection. This article will deeply analyze the technical innovation of the chocolate tempering process in the current market, especially the continuous chocolate tempering machine with high automation and outstanding energy-saving effect, so as to help global customers better grasp the purchasing direction.

Industry Focus: The Rise of Chocolate Making Machine Manufacturers

In order to meet the growing demand of the global market, chocolate-making machine manufacturers are constantly optimizing their technology. Major manufacturing countries have their advantages in automation and system integration. The following are some representative features:

Technical Analysis: What Is the Chocolate Tempering Process?

temperature, cocoa butter can form stable crystals, thus making chocolate shinier, crisper in taste, and more stable in storage. Traditional manual temperature adjustment is easy to mistake, while modern mechanized temperature adjustment adopts heat exchange technology, which ensures stable quality through three stages of preheating, cooling, and reheating, while reducing operation difficulty and labor cost.

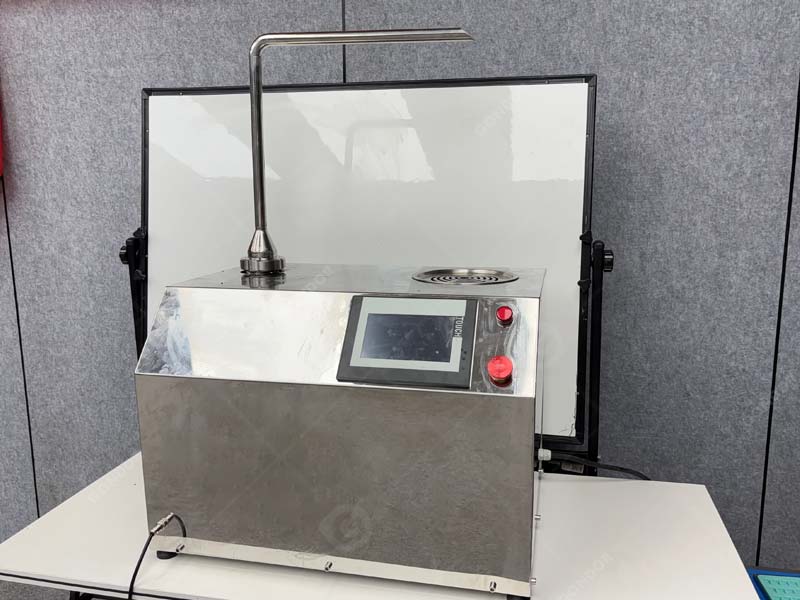

The First Choice for Efficient Production: Continuous Chocolate Tempering Machine

Compared with traditional intermittent equipment, the continuous chocolate tempering machine has become a hot spot in the market because of its advantages of continuous production and energy saving. It can run without stopping for 24 hours, significantly improving the production capacity, and is especially suitable for large-scale production in the peak period of holidays. Our latest model is equipped with a PLC intelligent control system, and the temperature control accuracy reaches ±0.1°C, ensuring stable chocolate quality and smooth appearance.

Integrated Upgrading Trend of Supporting Equipment

When building a complete chocolate production line, only the tempering machine is far from enough. Customers can also focus on the following efficient equipment combinations:

- Chocolate Molding Machine

- Chocolate Enrobing Machine

- Cocoa Liquor Grinding Machine